Beginning as a supplier of components for temporary structures to the armed forces in the 1950s, F G Parker’s state-of-the-art facility provides edging, wrapping, cutting and drilling facilities, providing the flexibility and service standards required by customers all over the country.

As a family business with third generation Rob Parker now managing the operation, F G Parker’s business successfully diversified into furniture manufacturing in the early 1980s providing products and services to help manufacturers find greater productivity in their businesses.

The Dorset firm has continued to develop within the industry supplying a full range of furniture components, mouldings, wrapped profiles, kitchen carcasses and cabinets, cutting, edging and CNC machining services to its clients.

In order to provide the flexibility and service standards required by today’s customers across the country, F G Parker’s 20,000 sq ft impressive production plant is home to highly advanced CNC routing equipment, the very latest CAD/CAM capabilities and high performance edging, wrapping, cutting and drilling facilities.

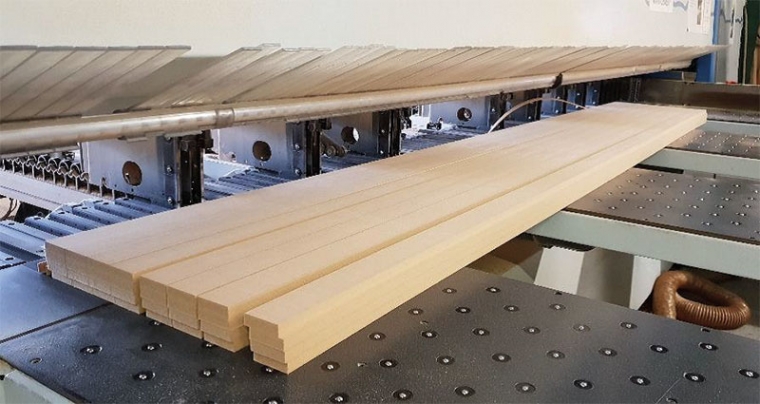

Drilling rails

F G Parker’s specialist drilling and boring machines enables the company to offer various holes drilled to any area of any-sized cross ties, post, mullion, front rail and back rail. Additionally, it is able to drill longer-sized rails up to three metres long – its rail drilling department is able to cope with high volume orders as well as small batches.

60 x 36mm mullions or centre posts for kitchen carcass

Rob Parker points out: “As standard, we produce many colours to get the perfect posts for the kitchen design. We hold in stock 36 x 36mm and 60 x 36mm but we can make to any specification. We can add drilling and/or we can cut the lengths down to fit any carcass size required – or just supply long lengths.

“Customers can also save time on their edge lines and get us to wrap small rails. We can even cut and drill them to customers’ drawings which will save significant man hours.”

Wrapped profiles

Wrapped profiles are typically used for cornice, pelmets, skirting boards, picture frames, small rails for kitchen and bathroom cabinets and drawer wraps.

“We can wrap many MDF and chipboard products in a variety of shapes and sizes,” explains Rob. “This process means that we can supply a post, rail and/or cornice to match any style. Additionally, the product can be wrapped all the way round giving a very tidy look to any cabinet, whilst at the same time keeping the cost low.

F G Parker operates multiple PUR glue lines for a high-quality, cost-effective product. The benefits of using PUR glue on wrapped products is that it provides a high strength bond, moisture resistance and reduces the danger of humidity interlacing. This process increases the standard lifespan of all its products compared to those manufactured with other glue types.

“We have a large range of foils available to us from PVC and paper coloured-matched to real wood veneered foils. Working with our foil suppliers, we can match many colours including plain, high gloss and woodgrains. Regardless of small or large order quantities we will be happy to assist with customers’ enquiries,” says Rob.

Edging

“With direct trade accounts with Egger and Kronospan, we are able to source a wide range of décors and matching edging to fulfil customers’ particular specifications, meeting any size and quantity required.

“All our edging is adhered using PUR glue, the benefits of which are that it provides a high strength bond and moisture resistance. Additionally this type of glue offers a minimal glue line between the MFC and edging, but ensures the product can withstand the rigours of heat and moisture over a long period of time,” points out Rob.

“We have a large range of edgings available to us from ABS to real wood veneers. Working alongside our suppliers, we can match most colours and finishes including matt, high gloss and woodgrains.”

Regardless of small or large order quantities, F G Parker is able to assist with customers’ varying requirements.

Panel cutting

“We are specialists in cutting MFC and chipboard/MDF raw boards,” says Rob. “On our high-speed automatic beam saws and automatic crosscut saws, we are able to meet the vast majority of customers’ requirements.

“We use the latest in optimisation software to minimise waste and optimise cutting lists so that each panel can be cut accurately and efficiently. We can source the material and décor for you, but can also provide a cutting service for materials that you have already purchased yourself,” concludes Rob.

01308 422987

www.fgparker.co.uk