Weinig's new Cube 3

.

Taking centre stage at this year’s Holz-Handwerk, Weinig Group exhibited a wealth of ground-braking technology on its impressive and busy 1600m2 stand.

The interactive stand, which was shared with panel processing machinery specialists, Holz-Her, demonstrated over 30 machines and innovative software and digital solutions, including the brand new Cube 3 automatic planer and Conturex Vario XS.

XS Machine, XXL Possibilities

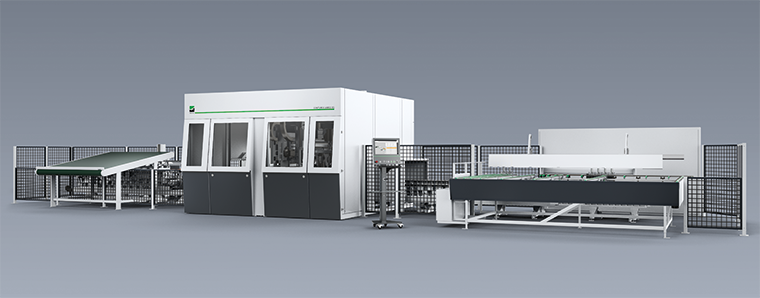

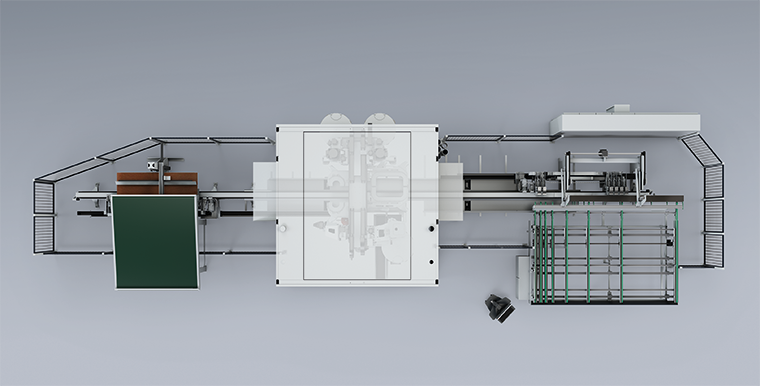

The Conturex Vario XS is the latest addition to the long-standing Conturex range and the most compact to date. Launched in response to current trends in the window market, the XS has been designed with smaller manufacturers in mind.

Benefiting from the same advanced technology used on larger industrial models, the XS offers exceptional machining versatility while benefiting from a remarkably small footprint.

It’s capable of working with lengths from 175mm to 4500mm, widths from 20mm to 330mm and workpieces up to 6m in length. It also features PowerGrip Motion 2D/3D software enabling complete processing in a single clamping procedure and full freedom of the X, Y and Z directions with no additional set-up, making it suitable for batch one and series production as well as just in time manufacturing.

3 Is the magic number

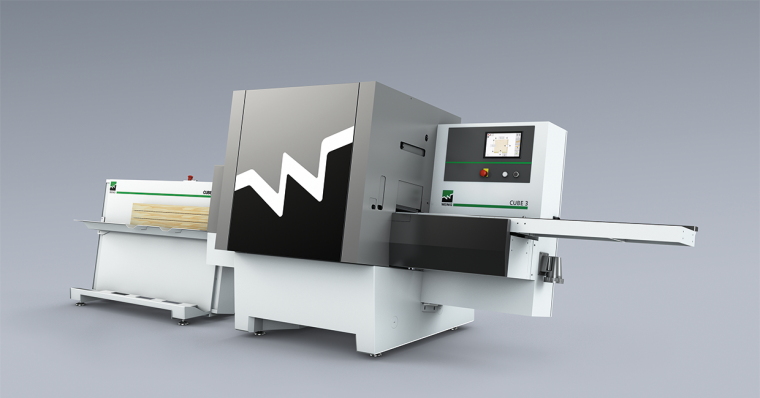

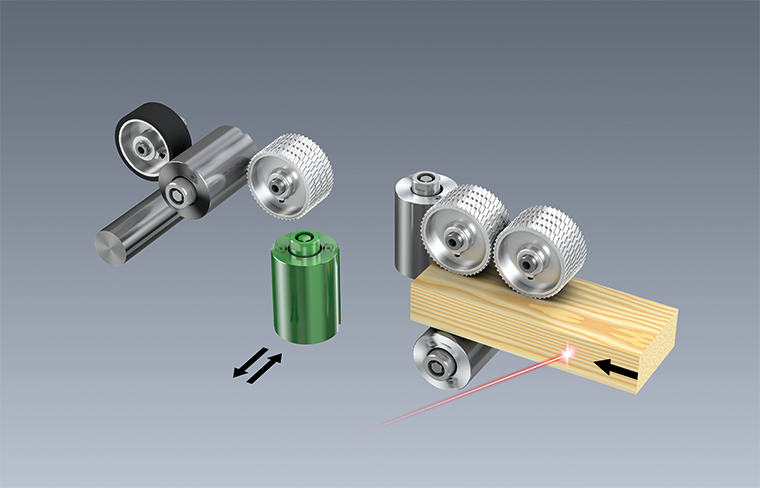

The third generation plug-and-play Cube 3 has been designed to offer bigger time savings, even simpler operation and enhanced standard equipment for an even better price-performance ratio.

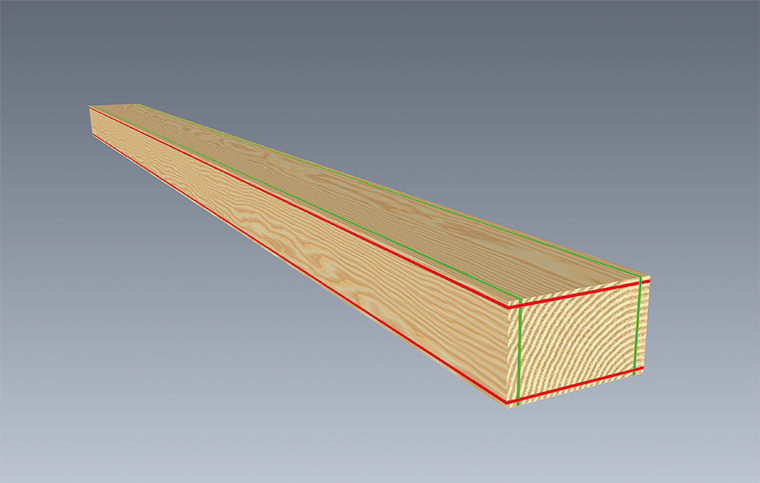

The plug-and-play Cube 3 can be tailored to suit your production needs now and in the future, while always guaranteeing perfectly right-angled workpieces

The trusted model, which was first launched over a decade ago, also offers more flexibility than ever before with performance-enhancing features that can be retrofitted to the compact planer if/when your production requires them, unlocking the full potential of the machine.

From automated stackers to return conveyors for safe one-man operation, your Cube 3 can be tailored to suit your production needs now and in the future, while always guaranteeing perfectly right-angled workpieces.

Epic safety technology

Making its debut at Holz-Handwerk, Holz-Her’s revolutionary SafeDetect technology was demonstrated on its newly extended Epicon CNC range.

The introduction of SafeDetect means the operator can benefit from free access to the machine even when it’s running at full speed because the space above the machine table as well as the area in front of the machine is monitored for all-round protection.

![]()

Holz-Her’s clever SafeDetect technology was shown on its Epicon CNC range

Laser lines projected on the floor in real time continuously show the operator the safe zone surrounding the machine head. If this is encroached, the machine will stop, keeping the operator safe.

What’s especially impressive is that unlike a machine equipped with a bumper system that needs to run at a very slow speed and needs to make contact with the operator to stop,

SafeDetect runs at full speed, reducing as it gets within 1.4m of the operator and stops fully when within 700mm of the operator. When safe to do so, it will continue where if left off. Dust and offcuts do not trigger the stop phase as radar technology is in play.

Connect with Weinig

Available as a web or mobile application, the Weinig App Suite offers a wide variety of functions to keep you informed, including machine monitoring, trending, OEE, individual notifications and various analysis options.

The latest update, which was put to the test in Nuremburg earlier this month, allows interlinked machines, production lines, complete systems and even an entire factory to be operated fully automatically and digitalised from order entry to the end product.

With each function individually assembled and selected via a modular structure of the functions, each Control Suite is tailored to the operator’s needs for the ultimate Weinig experience.