The Profimat 50 from Weinig has arrived. Part of the all-new Profimat series, the Profimat 50 has been designed to offer small- to medium-sized manufacturers maximum performance and flexible production when planing and profiling all types of timber.

The Profimat 50 can be equipped with an intelligent control package that’s ideal for frequently repeating products. A 10.1in touch screen display offers clear user guidance to set profiles at the touch of a button. Motorised CNC controlled axes provide automatic setting for planed-all-round production. As standard, the machine is controlled manually.

.

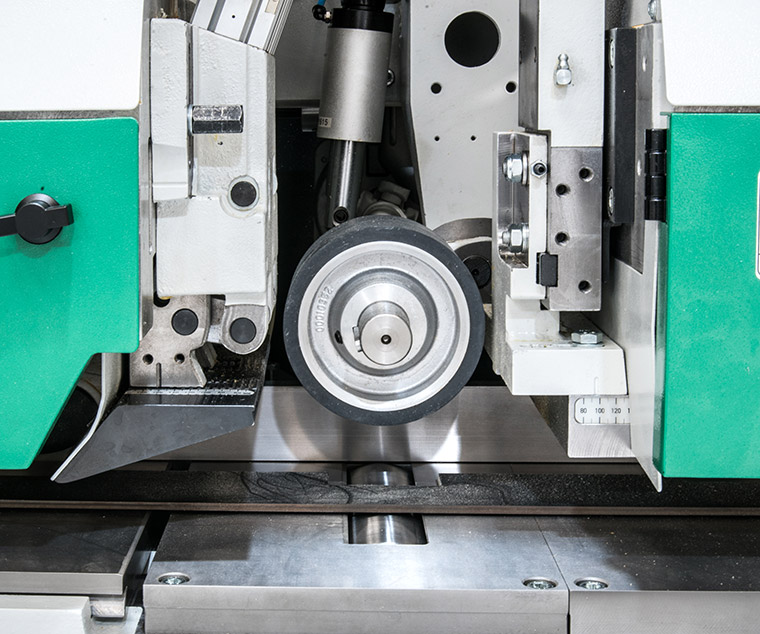

With its robust cast iron machine base and precision-machined spindles, the Profimat 50 ensures a high surface quality on all workpieces, whilst sitting comfortably within an 8.8m square footprint.

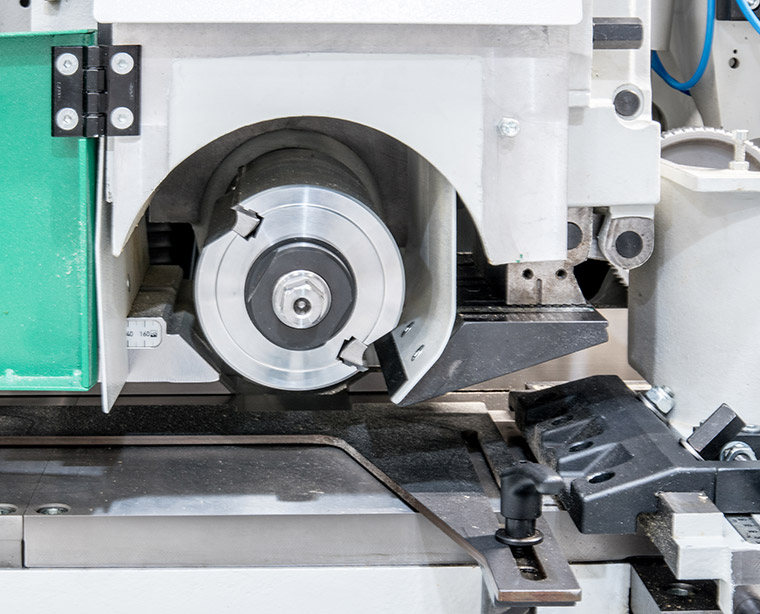

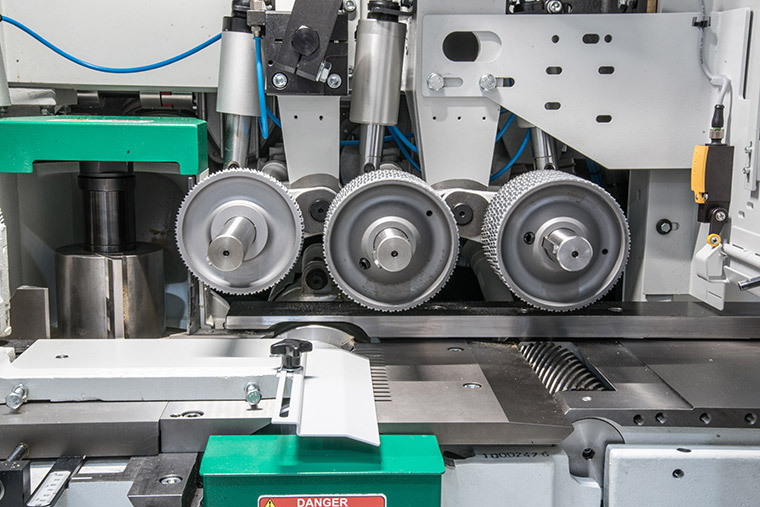

The robust moulder, which is fully customisable and is offered with optional tool packages, has been designed to work up to 260mm wide – the width of a stair tread and, in many cases, a window board. The new model can be specified with five or six heads and powerful motors up to 15kW.

With its robust cast iron machine base and spindles, the Profimat 50 ensures a high surface quality finish from a compact machine footprint

The five-spindle model has a frequency controlled feed speed of 30m/min and a spindle speed of 7000rpm as standard with 8000rpm available if 15-33% more production is required without any reduction in surface quality.

The moulder also comes equipped with a manually adjustable 6mm lateral guiding fence, adjustable table plates and an easily adjustable fence after the right spindle. A driven table roller in the outfeed adds to the quality of the finished product.

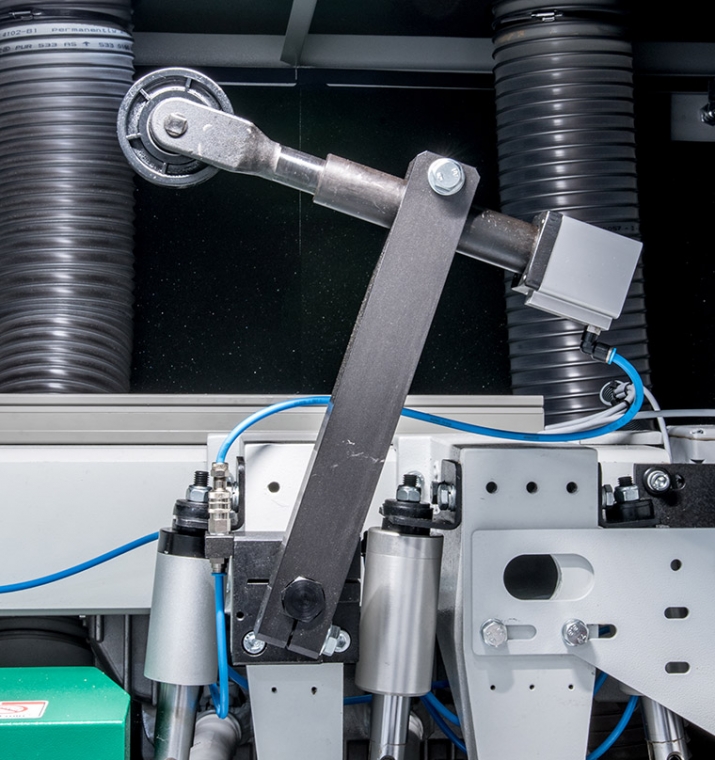

The Profimat 50 can also be equipped with an optional groove guide for short or difficult workpieces, a 2.5m straightening table and an optional 1.2m infeed table with three-roller infeed to process large dimensions or wet timber effectively.

For further ease of use, the new model comes with Digi-Set and machine read-outs as standard. An optional control package with Memory Plus and electronic digital read-outs is available, offering CNC-controlled axes for the automatic adjustment of the width and thickness for planed-all-round production.

Whilst offering the user a wealth of innovative technology at their fingertips, the Profimat 50’s electrics have been designed to offer high energy efficiency without limiting performance. The use of frequency converters to start and stop all spindle drives reduces power peaks during start-up and switch-off while reducing the thermal stress of the motors when braking the spindles. It also means less energy is used when operating at partial load, making this model highly energy efficient.

The Profimat 50 has been engineered with low-maintenance components for exceptional reliability, quick adjustments and low running costs. It features a feed system with separate drives for quick and easy maintenance and a fully detachable dust extraction hood that not only leaves the left spindle easily accessible for tool-changing but also helps to reduce extraction energy consumption by 20% when compared with a 140mm hose on the same model.

The Profimat has a 230mm working width, or an optional working width of 260mm

Malcolm Cuthbertson, MD of Weinig UK says: “The Profimat 50 is a development of Weinig’s Profimat series. Following on from the launch of the compact Profimat 30 last year, this model offers small to medium-sized manufacturers flexible machining and precise, fast planing and profiling. Users can expect to find a wealth of technology at their fingertips that, until now, has only been available on larger moulders in the Weinig portfolio.

“Designed and manufactured entirely by Weinig’s in-house engineers, the Profimat 50 offers the speed, reliability and quality needed in today’s market. This, partnered with a price tag of just £42k, offers manufacturers an affordable way to boost performance, precision and safety, whilst opening the door to a diverse range of revenue streams.”