Part of a growing series of machines, the powerful Conturex Artis is an entry-level CNC single component production system that offers small to medium-sized window and door manufacturers a complete solution for machining individual components, proving you don’t need to sacrifice flexibility, when producing small batch sizes.

Brimming with innovative features designed to assist in the processing of corner joints, longitudinal profiling, drilling, shaping and insert shaping all in a single cycle, the Conturex Artis and Conturex Artis+ provide a wealth of advantages at an optimal price/performance ratio.

Offering complete automation at the press of a button, the Conturex Artis facilitates tool-free machine setting and is perfect for small batch sizes and window production. When switching from one window component to another, no jigs or fixtures are required and there is no need to re-set the tooling or machine.

The Conturex is fitted with an infeed buffer loading system, making it a virtually un-manned machining cell. This not only eliminates the downtime associated with loading, unloading and retooling but also reduces the number of operators needed and the level of skill required to set-up and run the machine efficiently. The result is a highly flexible machine that comes with significant time-saving credentials and risk-free machining.

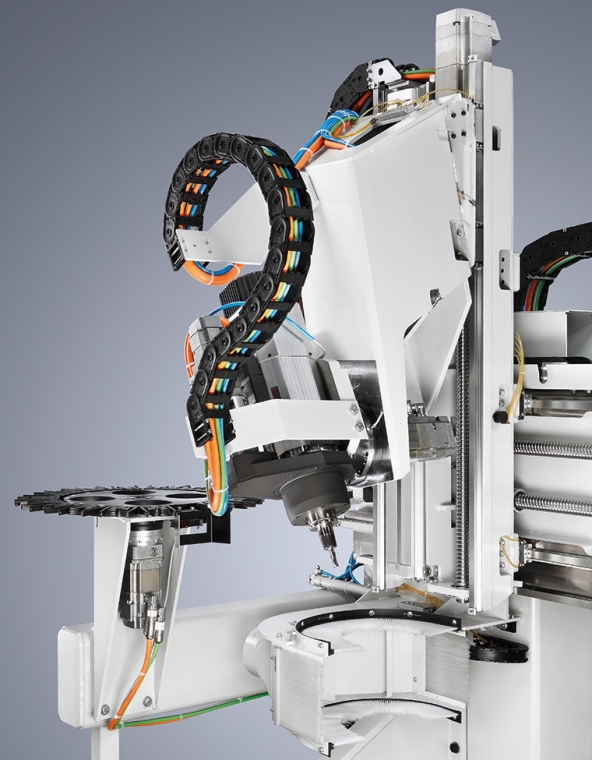

Universal spindle with five-axis technology

Capable of machining lengths from 175mm to 3500mm as standard and work pieces of up to 4500mm in length if required, it also features a standard three or four-axis 30kW main spindle that allows profiling to be carried out in a single step (a universal 17kW spindle with five-axis technology is also available on the Conturex Artis+). In addition, the air-cooled main spindles require almost no maintenance and ensure easy access for fast tool removal and replacement. Thanks to the indirect drive, the motor is always protected even in critical situations, making the Conturex Artis an extremely reliable and cost-effective machine to run.

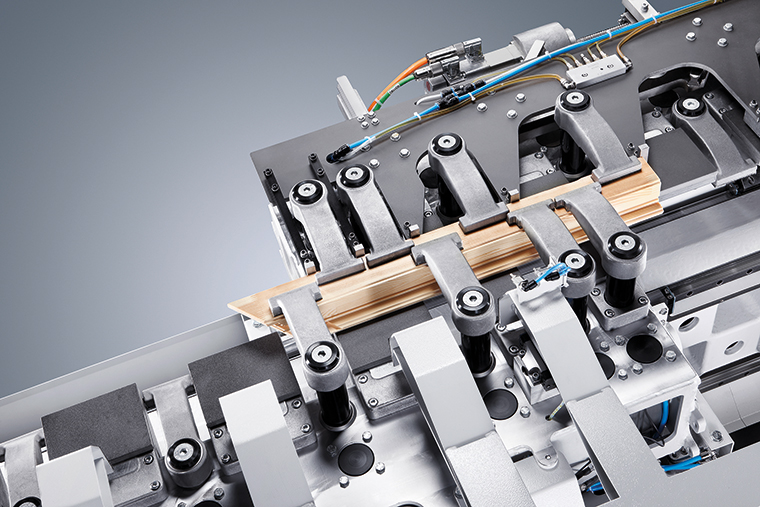

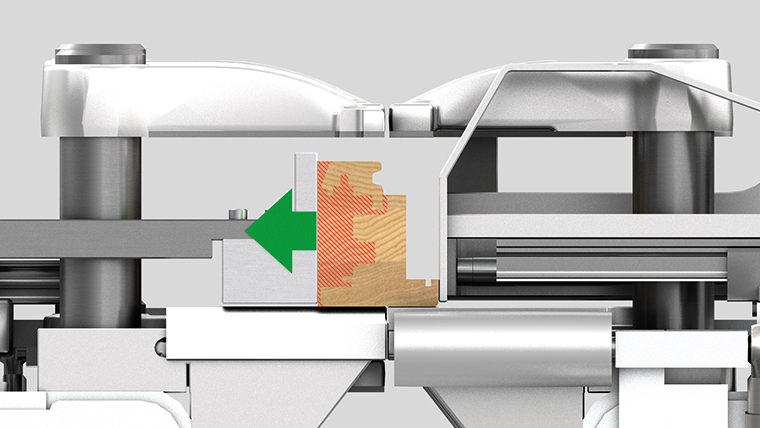

The Artis and Artis+ offer complete and precise machining in one clamping process thanks to the RePos clamping table. The patented technology allows variable clamping of the workpiece and automatic movement of the machined pieces inside the machine, providing maximum precision and quality even on thin profiles and new architectural window systems.

Power Grip RePos easy offers even more flexibility with thin profiles and new window systems

Corner joints have been made simple: choose between mortise and tenon joints, dowel connections and mechanical corner joints. With a maximum tool diameter of 340mm and tool weight up to 12kg, mortise and tennon joints can be created with absolute precision and, with a maximum slot depth of 140mm, this technique can also be used for doors.

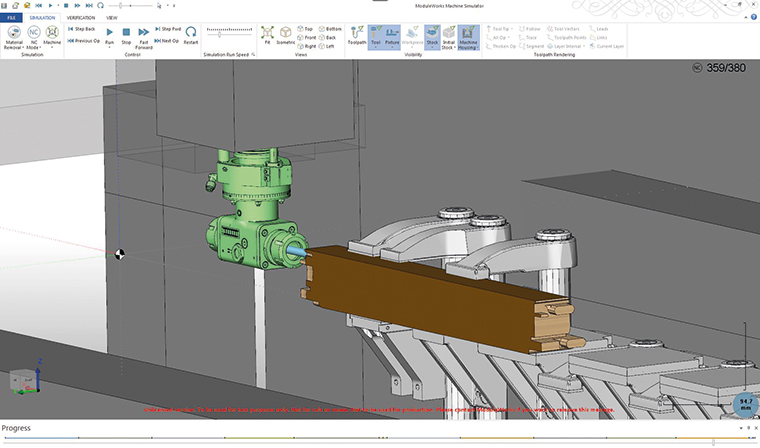

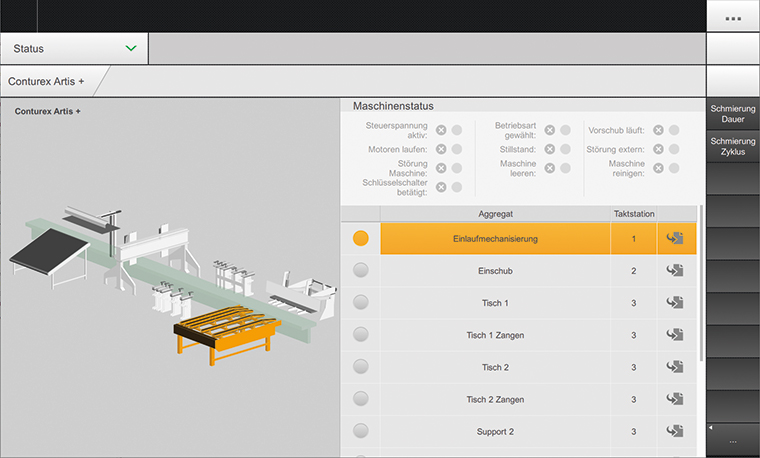

The Conturex Artis and Conturex Artis+ package is completed with a user-friendly WMC control interface, which includes Weinig CAM, a complete and easily programmable 3D CAD/CAM system for customised designs. Additional features also include Weinig Sim simulation software – designed to highlight potential errors during the running cycle – and energy recuperation modules that offer significant savings in energy.

Weinig SIm offers more conveniene and safety through visulation of production data

WMC Control offers a user-friendly interface

Malcolm Cuthberston, Managing Director of Weinig UK explains: “Traditionally, workshops relied on the use of multiple machines, including a moulder, tenoner, morticers and spindles to create window and door profiles. This meant a window or door component may be manually handled around eight times before all the machining was complete. Weinig’s Conturex series has streamlined this process and even the entry-level Conturex machines are equipped to run for 20-30 mins without any human intervention.

Weinig understands the importance of flexible machining in the windows and doors market. Mass-produced windows and doors have long become the exception and the need to fulfil small batch sizes is now expected. This, along with the issue of work space, the ongoing skills shortage and the need for precise accuracy, has seen the series grow in popularity. It’s no wonder over 3500 Conturex machines have been sold across Europe.

The Conturex series takes on milling, drilling, machining of corner joints and lengthwise profiling with utmost precision, full automation and high flexibility, doing the work of five machines in one while significantly slashing production costs and increasing profit margins. This really is a complete solution at an attractive price point.”