A “brilliant and very clever tool” is how Dominic Ash, owner of Dominic Ash Ltd, describes Cabinet Vision, as the business looks to the future with new draughtsman, Ed Muir.

Dominic Ash Ltd are an internal architectural joinery company operating from an 8000 sq ft manufacturing facility, based near the village of Yanworth in the Cotswolds. The company, which has been established for over 20 years, is owned by Dominic Ash and his wife Kate, who work with six employees to create high-quality, impressively designed furnishings for interiors.

Its vast range of bespoke creations includes kitchens, wardrobes, staircases, tables, chairs, free-standing pieces of furniture, built-in book cases, and internal doors. Its client-base include professionals such as architects and interior designers, as well as individuals looking for beautiful bespoke furnishings for their home.

Dominic Ash says: “While we do focus on high end cabinetry, we also offer some basic products. A couple recently wanted some very high end products such as a high-end kitchen and fireplace surround, but more basic items for their utility room, so I can cover both aspects.”

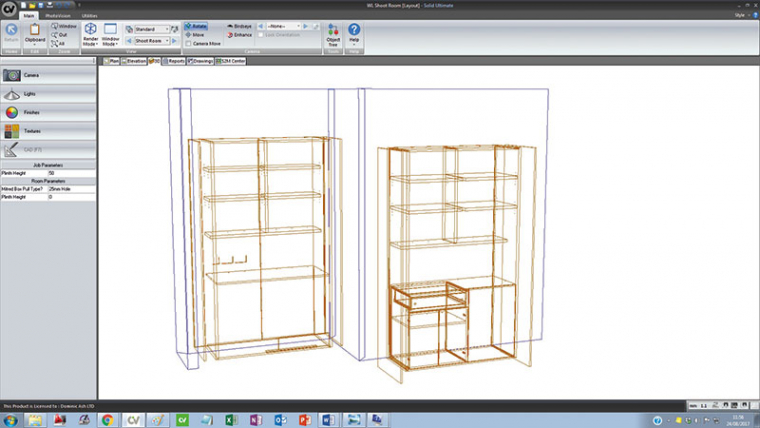

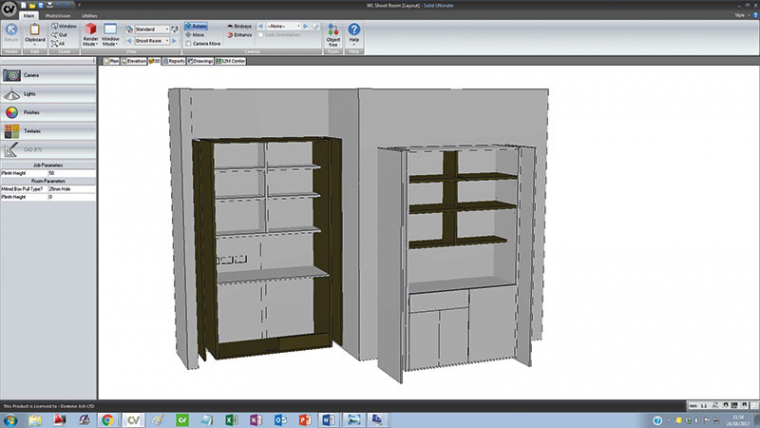

Within the manufacturing process, Dominic Ash Ltd uses Cabinet Vision and Screen To Machine to produce all cabinetry from plywood, MDF and veneered MDFs. The company chose to invest in Cabinet Vision a year ago to make its processes more efficient and remove human error.

Dominic says: “It’s very important to us that each component is high precision so they can assemble perfectly.”

Before implementing Cabinet Vision, the many processes involved for each job were time-consuming and repetitive. “We were trying to eliminate some of those processes and the human error.

Previously we would draw everything in CAD, break it into the components for the CNC machine, put those into a DFX file and load that into the proprietary software as individual pieces, and then through into the CNC to create nests. Cabinet Vision speeds up the process and does away with the need for manual cutting lists.”

Now its CAD designs are imported into Cabinet Vision where the cabinets are created, and then Screen To Machine sends the NC code to its three-axis Biesse Skill CNC router.

The company had been seeing time benefits and was enjoying a streamlined manufacturing process until recently when its trained Cabinet Vision user left the business. It is now eager to evaluate the situation and get up to speed again with the support of its new employee, draughtsman, Ed Muir.

Although Cabinet Vision is an extensive system with wide-ranging functionality, Ed Muir is finding it easy to learn with no prior experience of using the software, although, he says, there is a steep learning curve.

“Cabinet Vision’s best feature for me, is keeping everything within the master template. It’s very quick to be able to adapt the template to work on a particular job. You can change any element of a cabinet, which makes creating new cabinets so much faster. You can easily adapt and change any part of an existing cabinet using the parametric function.

”This ensures that once a panel or cabinet is created in Job A, if Job B involves a similar cabinet, the parametric function allows us to take the item from Job A and move it to Job B, adapt the size, and everything else will follow suit.”

Due to the many bespoke items that the company produces, Ed Muir says: “We have different templates of different materials for construction as well, so it’s really simple to drag and drop.”

The company is now setting the foundations to take the business forward with Cabinet Vision, and possibly utilise more of what the software has to offer. It is aware that investing time up front will pay dividends later, as previously it had been more focused on using it, rather than on how it was going to use it in the future.

Dominic envisages that Cabinet Vision will be an integral part of its processes in the years to come as they continue to explore new functions of the software.

“It’s a brilliant and very clever tool. I can see a lot of benefits in it and it’s probably everything I thought it was going to be. For us, we’re not a factory producing the same item time and time again. We’re creating new items and new methods all the time, so we’re probably exploring Cabinet Vision a lot more than the average user would.”

He has also been impressed by the speed of the software when converting designs into CAM and accurately sending NC code to the router, as well as the “superb” support the company received.