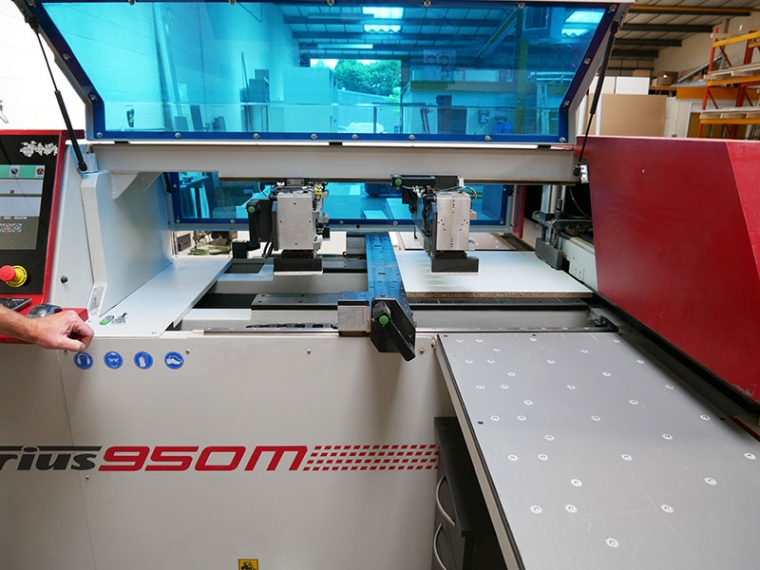

Galaxy Interiors is a young business focussed on kitchen, bedroom and office furniture manufacturing. Using a traditional multi-borer to drill cut and edged panels was becoming problematic – the solution came in the form of an AES Sirius 950M point to point boring machine from local supplier J & C O’Meara.

Ian Makinson with his son, Alex, in front of his new AES Sirius 950M CNC drilling machine

“Our business began through necessity,” explains Ian Makinson, managing director of Leyland-based Galaxy Interiors, “my wife and I were looking to furnish our own home. We found affordable furniture but the quality was poor and with limited choice of colours and styles – whereas the furniture we liked was far too expensive. So I set out to do better myself!”

Ian established the business, initially in his garage, then to a small unit and now to a 3000 sq ft premises with room to grow. With 23 years served as a bricklayer, Ian used his network from the building trade and is now fast developing a reputation for good quality replacement doors and full kitchens. Currently a lot of his contacts are using Galaxy Interiors as a local, reliable, quality-oriented designer and manufacturer.

The machine has a large industrial based 17in colour windows based PC with both USB and remote file transfer.

In the 18 months since he started, Ian naturally had to evolve the operation.“In terms of equipment, I have an Altendorf panel saw, a Robland edgebander, and my latest machine, an AES Sirius 950M CNC drilling and milling machine.”

Supplied and installed by Burscough-based J & C O’Meara, the AES Sirius 950M point to point boring machine is a high quality machine designed for flexible drilling and routing applications. It provides a cost-effective solution for kitchen and bedroom furniture manufacturers who can typically cut and edge panels efficiently but then bottlenecks develop because of having to use traditional boring machines or manually marking out, drilling and screwing – slowing the process down and increasing the potential for errors and quality issues.

“Before I bought the Sirius, I didn’t realise Carl (O’Meara) was only down the road in Burscough – they’re only 12 miles away. In retrospect, I think I paid over the odds for a machine or two in the early days, and the after-sales on those has been quite poor. Whereas with the Sirius working with Carl and the guys at J & C O’Meara has been really superb, first class!”

Ian says that the multiborer he used before getting the Sirius was slow and quite a challenge: “There were so many settings to do and you had to remembered them for the interlocking – it was quite mind-blowing at times. I really needed to upgrade this part of my business as it had become a chore. By comparison the Sirius is so easy to use – it has speeded up our work dramatically and has made the product much better too because it’s so precise,” he explained.

The Sirius machine has a heavy duty construction weighing almost 1.5t ons which is reassuring when it can operate at speeds up to 70m/min. Even large panels are loaded and move through the machine with ease thanks to the air flotation tables and are firmly held for positioning by the pneumatic gripper.

The machine has a generous 950mm working width and is equipped with 10 vertical drills, which drill from below to ensure the working surface and all holes are kept dust free whilst also having the benefit of increased accuracy as the drilling depth will always be correct despite any tolerances in the thickness of the workpiece. The machine is also equipped with horizontal drilling to all four sides and a grooving saw for the X axis.

Carl O'Meara (left) from exclusive UK distri talking with Ian Makinson

With the addition of the optional router head, a range of tasks can be easily resolved such as grooving for solid backs on carcasses, routing out for cable management, pipes or skirting and shaping for corner units.

Galaxy Interiors now has the drilling solution to help its business grow

Ian sees his Sirius investment as extremely worthwhile: “We really needed to change how we were getting this part of the job done,” he says, “we had to achieve a better drilling option than what we were doing before. With the brilliant Sirius it’s done in a fraction of the time and the quality is spot on and it’s easily repeatable. I would definitely recommend one!”

01704 893109

www.ukwoodworkingmachinery.co.uk