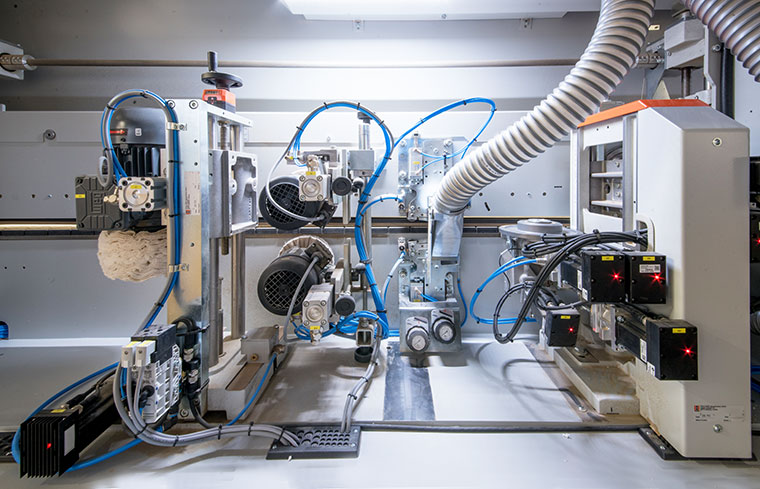

Lumina 1598 with Return-Master 5920 panel return system

.

Norfolk Oak prides itself on doing things differently. Creating up to 150 bespoke kitchens every month from its 100,000sq ft premises in Fakenham, the kitchen manufacturer has carved out an enviable niche, offering high-end kitchens and doors to architects, designers and residential clients online.

But, when faced with the challenge of applying a paintable PVC edging to a smooth panel door, Norfolk Oak turned to Holz-Her UK for the solution.

Jamie and Jayne Everett

“I don’t buy equipment, I buy solutions to problems,” admits Jamie Everett, MD of Norfolk Oak. “We needed to apply a PVC edge to a panel door which, in turn, would then be painted. On the surface, this may sound simple, but with a flat, smooth door, we use a HDF substrate. The surface layer is made from melamine, which is made up of 30 layers of craft paper, with each layer glued and pressed together. It gives you a really lovely, smooth finish, but, when you cut it on a CNC, you end up with HDF edges.

“When you’re using water-based paint to finish the door, it fluffs up and makes it difficult to work. If you don’t get the glue line and edge down to two or three hundredths of a millimetre, you’ll see every single imperfection once it has been painted. For us, that was simply not an option. We needed an edgebander that could apply a perfect, paintable edge to our door panels quickly and efficiently.”

Having worked with Weinig UK for 15 years, purchasing both solid timber machinery and, more recently, panel-processing equipment (including three flatbed CNCs and a pod-and-rail CNC from its sister company, Holz-Her UK), Jamie understands the importance of investing in good quality equipment.

“Our thought processes are completely aligned, and I trust them implicitly,” he says. “That’s why they are my go-to problem solvers. They said we needed a Lumina 1598 with a ReturnMaster panel return system, and they were right. It ticks every box, and offers an absolutely perfect edge, every time.”

So, how did the Lumina 1598 help Norfolk Oak achieve its objective?

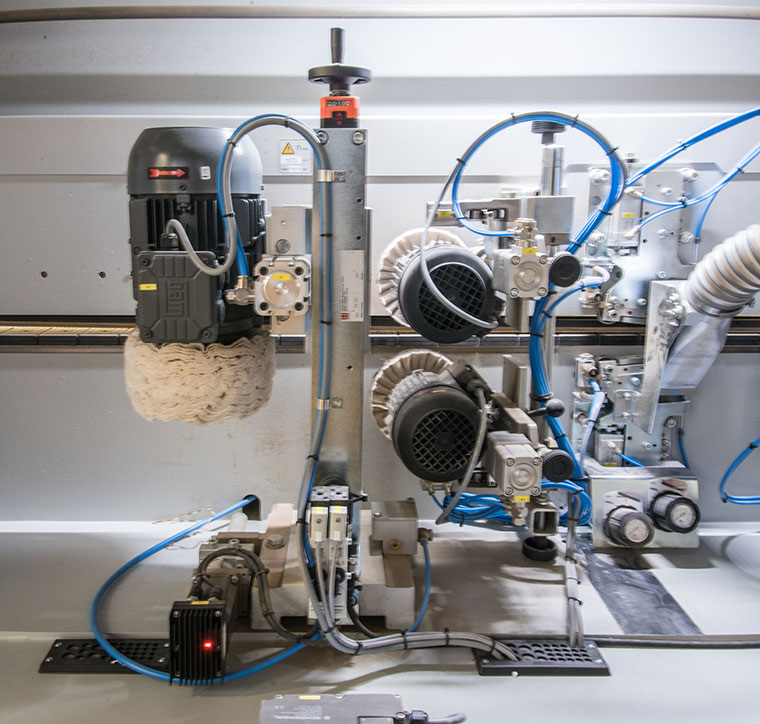

As well as being fitted with a patented GJ 702 Glu Jet system, capable of working with EVA and PUR cartridges and granulates to reduce downtime and glue cost, the Holz-Her edgebander comes with a wealth of automated features to provide enhanced speed, accuracy and versatility.

The GJ702 GluJet system

The Multipurpose Package delivers automatic, program-driven profile changing to the fine trimming, corner rounding and profile scraper units (changing from 1.3 to 2mm to 45° chamfer to 8mm flush).

The edgebander also includes iTronic as standard. This facilitates adaptive precise pressure to the pressing station, and glue quantity control to the GJ702 Glu Jet. The result is a repeatable (by program recall) glue dose, for a near-zero glue line.

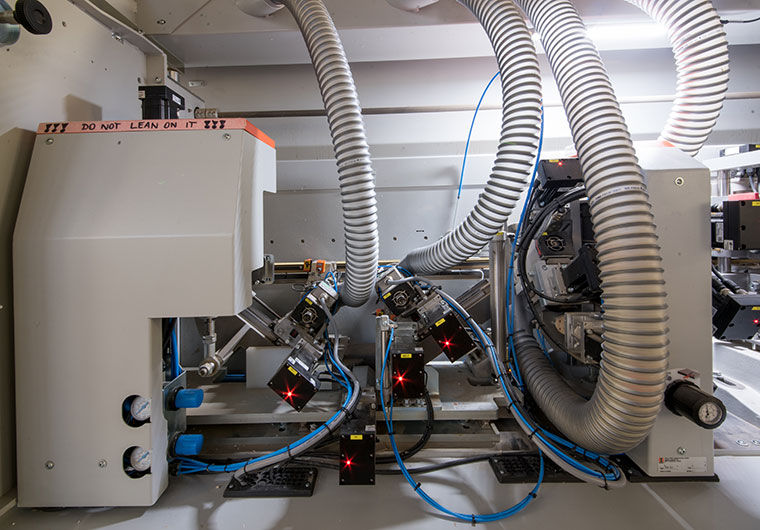

The Lumina's end trim unit, flush trim unit and fine trim unit

It also features automatic remaining glue coverage monitoring and an automatic flush feature for easy cleaning of PUR. The machine’s fa.s.t technology also allows for different operations to be carried out while panels are still within the machine. This means the operator no longer has to wait for panels to exit before moving onto the next production phase.

Plus, with finishing units – including an extra set of buffers for the rounded corners and sprayers – this machine delivers finished panels to an exceptional standard.

The Lumina's finishing section which includes profile scrapers, surface scrapers, top and botton buffers and corner buffers

“The automated processes make this a phenomenally quick piece of kit,” says Jamie. “Capable of running at 25m/min, one operator can run a whole kitchen – normally 200 panels – through the machine in under an hour. The same process would have taken two people at least 2.5 hours on our old machine.”

Two motor courner rouding unit

The ReturnMaster panel return system makes one-man operations easy, but it is also providing other important benefits, says Jamie: “It was a big investment – around 35% of the total cost of the package – but it’s around five times faster than its predecessor. This offers huge labour savings, and by that I don’t just mean an operator’s hourly rate. It comes down to cost and allocation of resources, too. I predict that the whole setup will pay for itself within two years, probably sooner.”

Top and bottom and corner buffers for a perfect finish

The quality of the panels coming off the Lumina has also been a gamechanger for Jamie: “Our old edgebander needed to be manually adjusted with an Allen key, and it didn’t offer any automatic quality-control settings. It made the process more labour-intensive, and as a result, boards would often need to be pre-processed to eliminate visible imperfections.

Cleaning cartidge for neutralising PUR

“Since our Lumina 1598 was installed, we have had virtually zero remedials at the production stage and we haven’t had any customer remedials from our edging work, either. Automation makes this side of our production more efficient – the tolerances are microscopic and each panel is perfect before it goes to be painted. That said, we still hand-finish and check every panel for peace of mind. That will never change.”

Keen to continue the blend of traditional and modern manufacturing techniques, Jamie’s motivation to invest remains strong. “You can’t let old machinery and technology define your business model. You will get left behind. We are constantly trying to find new and innovative ways to do things that, ultimately, set us apart from the rest.

“In a manufacturing business, it’s not like steering a sports car, it’s like steering an oil tanker. You need to be a long way ahead of the curve to make sure you’re going the right way.

Lumina 1598 with Return-Master 5920 panel return

“Holz-Her has been instrumental in this. They work with me, not for me. Replacing old with new isn’t the right approach for me. We can’t afford to get complacent. We tell Holz-Her what we want to achieve, and they find solutions. They know their stuff, they understand our company, and it shows. But for me, above all else, they show integrity. It’s not a common trait to find in business, but if there is integrity, everything else will fall into place. That’s why we work well together.”

What’s next for Norfolk Oak?

We may be in uncharted waters with Covid-19 and Brexit, but Jamie has his next move clearly mapped out: “It may seem like a curious time to make investments in our manufacturing processes, but we don’t need growth to justify these purchases. Collectively, they will increase production speed, grow our capacity and offer us more control and organisation throughout our business.

“Financially, the period of return is too great for most people to want to do this. We want to do it because it will add to the smooth running of the operation and give us the flexibility to offer a broader range of products as the market demands. To me, that’s worth every penny. and with Weinig and Holz-Her by our side, we know we’ll always be leading from the front. ”