The latest AXYZ Infinite multi-purpose CNC combined routing/knife-cutting system from Telford-based AAG has recently been installed at one of the UK’s leading manufacturers of furniture and associated equipment supplied to the educational sector. The perceived higher performance capabilities and important new machining enhancements provided by Infinite were considered to be pivotal to the rapid business growth and commensurate increased productivity levels at the County Antrim, Northern Ireland-based Kindercraft.

The company employs mainly melamine-faced veneered MDF and birch plywood to manufacture a wide range of handcrafted, high-end products. These include both standard and bespoke classroom desks, chairs and tables (including those covering special needs requirements), general storage, fitted washroom and kitchen units, computer suites and reception area furniture.

The company’s in-house design service works closely with school equipment specification and purchasing authorities in selecting products considered most appropriate for the different pupil age groups to be accommodated. These include products in a wide choice of different sizes, shapes and colours, enabling the creation of highly individualistic design themes.

Installation of the AXYZ Infinite could be described as the apogee in a long-running and highly successful business partnership forged between AAG and Kindercraft.

In 2002, the company installed an AXYZ 4008 twin-head router to undertake work previously carried out manually. This was followed in 2006 by a need to upgrade to and replace with the larger-format AXYZ 6010 router, in order to meet an increased customer demand, culminating in 2020 with the addition of the latest AXYZ Infinite 6010 machine (incorporating a seven-station Automatic Tool Change system for work requiring multiple tools) that was necessary due to a further exponential increase in production capacity that a single machine simply could not handle.

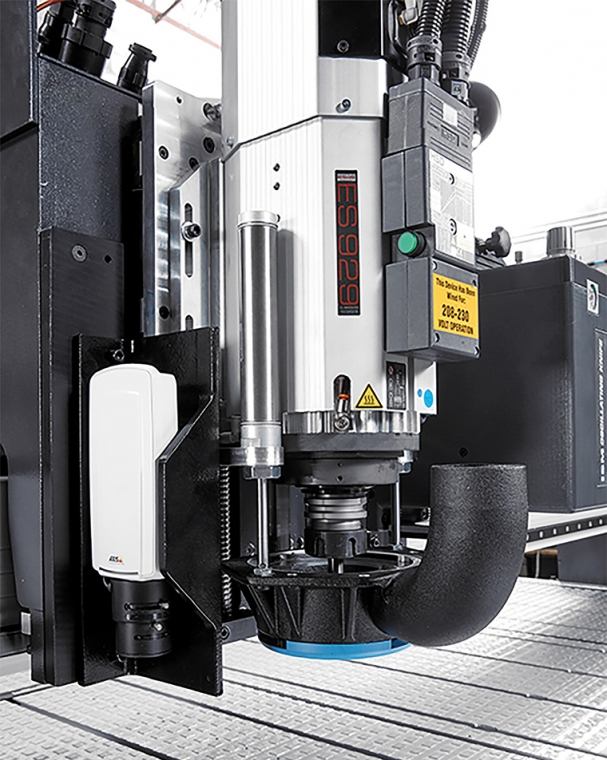

The AXYZ Infinite can be configured with a choice of single, dual or triple routing/cutting heads to accommodate varying application requirements. It is available in a choice of sizes and incorporates an expandable processing bed area of up to 3251mm in width by an impressive 15.24m in length.

Key design features include the familiar solid steel frame construction to withstand the most vigorous machine operation likely to be encountered, and an aluminium t-slot vacuum material hold-down facility.

These are supplemented with a new carriage design to enable easier routine machine maintenance and the installation of future machine upgrades, an ultra-efficient dust-extraction unit for enhanced machine performance, and a new misting system to provide improved machine cooling and lubrication.

Other optional production enhancements include the AVS (AXYZ Vision System) for optimum routing/cutting precision, and the latest helical rack-and-pinion drive system. This incorporates a multi-teeth configuration that helps spread the workload more evenly, resulting in faster material throughput and wastage and ultimately a longer-than-normal machine life.

01952 29100

www.axyz.co.uk