Sharps Bedrooms is one of the UK’s leading fitted furniture companies, with an annual turnover in excess of £125m. Founded in 1973, the company prides itself on designing and manufacturing bespoke fitted furniture that doesn’t compromise on maximising space, style or storage solutions for bedroom, office and living spaces.

“As a company, Sharps creates beautifully organised furniture designed specifically for each customer,” enthuses the company’s factory operations manager, Dave Lloyd. He continues, “To achieve this we have always invested in the best quality, most advanced woodworking machinery available. That is why we’ve been buying HOMAG equipment and software for more than 30 years.

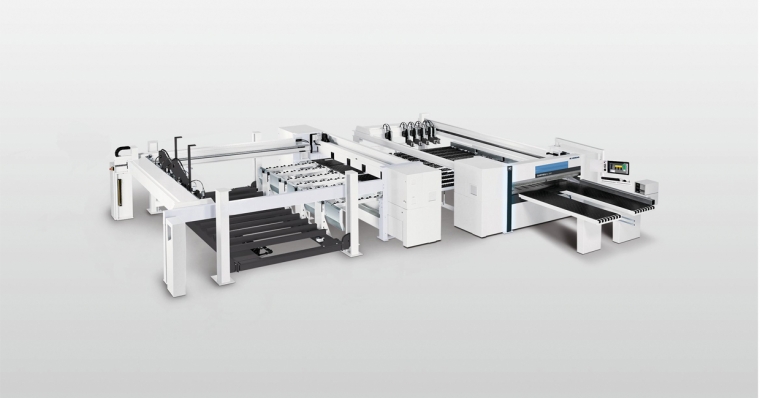

“Our most recent purchases from them have been a SAWTEQ B-300 panel dividing saw and a DRILLTEQ V-200 vertical CNC processing centre. The B-300 is a replacement for a HOMAG saw which had reached the end of its productive life.

“With regards to the DRILLTEQ V-200, we already had two HOMAG BHX 055s – now called DRILLTEQ V-200s – which were real workhorses in the business. However, because we have changed the way we manufacture certain products we needed a third machine to cope with the demand.”

DRILLTEQ V-200 vertical CNC processing centre

A simple selection process

“When it came to investing in another CNC drilling machine, we didn’t have to look further than HOMAG,” continues Dave. “The two CNC drilling centres we already owned were simple to use, totally reliable, efficient and continued to deliver first class results, so it was an easy decision to opt for a third machine.

“Although we already had three different HOMAG saws, we didn’t just place an order for a new saw with them. Instead, we looked around the market to see what was available. After completing our due diligence, we were still of the opinion that overall HOMAG offered us the best option for a new saw.

“In addition to the comprehensive basic configuration of the SAWTEQ B-300, there is a wide range of optional features that enabled us to configure the saw to match our specific production processes.”

SAWTEQ B-300

HOMAG provides a complete package

”HOMAG may not be the cheapest option in the market, but ultimately you get what you pay for, and with HOMAG you get an enormous amount for your money,” asserts Dave. “The machines are technically advanced, extremely robust and reliable, and the aftersales service is brilliant.

“Everyone we deal with at HOMAG is a true professional. From area sales manager, Matt Long, and the installation engineers and trainers, to the sales and support teams at Castle Donington, they go out of their way to help. To a person, they are friendly and easy

to deal with which makes doing business with them so much more productive and enjoyable.

“Freddie, the HOMAG engineer who installed and commissioned the machines at our factory, is a case in point. He is an absolute perfectionist. Before training our operators on site, he made sure that everything with the machinery and software was spot on. He was diligent and thorough, dotting every ‘i’ and crossing every ‘t’; there was no way you could fault anything he did.

“The new SAWTEQ B-300 and DRILLTEQ V-200 have made a big impact on our manufacturing capabilities. Their reliability, speed and quality have definitely made our manufacturing facility more efficient. The machines are doing exactly what we had expected and HOMAG continues to provide us with first class support. What more could you ask?” concludes Lloyd.

For a demonstration or further information on HOMAG woodworking machinery or software, contact Adele Hunt at HOMAG UK on 01332 856424 or email: [email protected] www.homag.com