Whether looking for a through-feed machine or a stand alone machine for routing, drilling or both, NEY can offer the right solution.

The Vitap Point has been designed and built to be a small footprint CNC machine capable of face drilling, edge drilling and grooving by blade in the X axis. With the addition of the optional router, cutting and shaping operations can be carried out with ease.

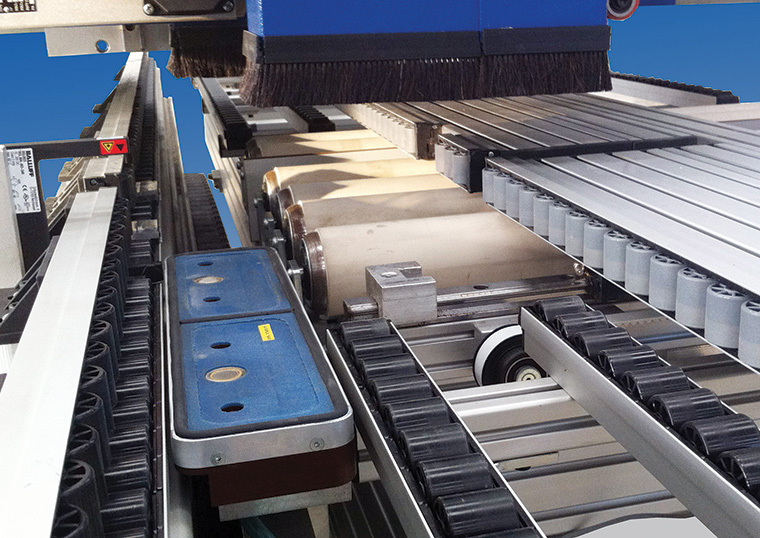

The Point 2 boring machine, is an intelligent solution at a very competitive price. It is a CNC controlled point to point boring machine with through feed, panel boring from the bottom and automatic panel return to the operator. The Point 2 is the affordable automatic through feed drilling machine that combines flexibility and high productivity, with no lost time on set up between jobs.

Thanks to the belt drive system, processing of long panels is seamless, with no clamp or unclamp delay. Double Zero Reference is a standard feature and the fact that the panel is drilled from the bottom means that hole depths are more accurate and assembly holes are perfectly matched as the drilling takes reference from both the leading and trailing edges of the panel.

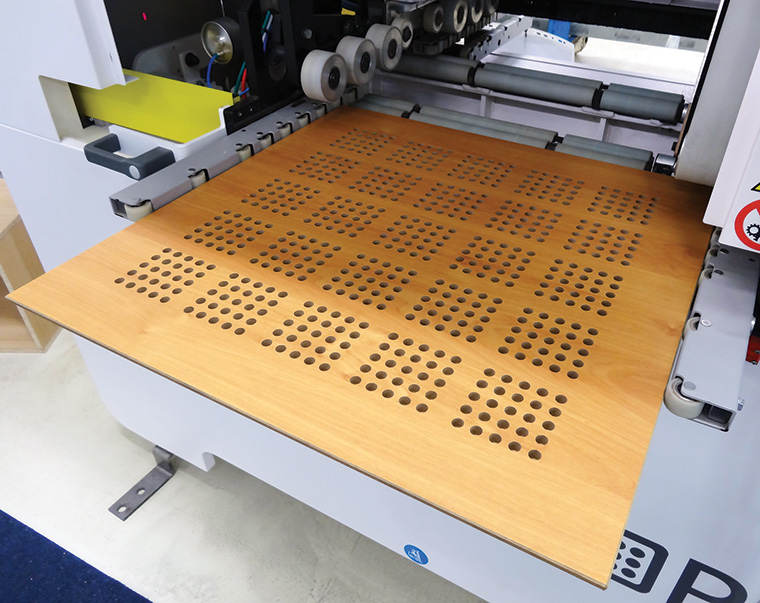

In addition to the Point 2 (max width 920mm) and the Point K2 (max width 1100mm) Vitap also offer the Point Acoustic which is designed for the acoustic panel sector and is capable of drilling 54 holes every four seconds in a through feed cycle.

Alberti is one of the most respected names in the industry and has been involved with the production of CNC solutions for drilling, routing and grooving for many years. The T-Flight machine is in a class of its own with respect to speed and ease of use.

With its compact footprint and intuitive software it allows medium to large size manufacturers to put in place a batch one philosophy.

A standard laser allows for exact measurement of the panel length which in turn will automatically compensate for dimensional errors in the panel. Whilst the machine is essentially a vertical and horizontal drill, aggregates such as grooving and routing can be added to enhance production. Programming and management of the machine is via Albatros TPA-ED32 software.

The programming system enables individual programs or work lists to be selected and, if required, recalled by reading a label containing a bar code thus enabling production per order one part after the next, going directly into assembly or into a flat pack area. No time is lost between job changeover, saving time and increasing productivity.

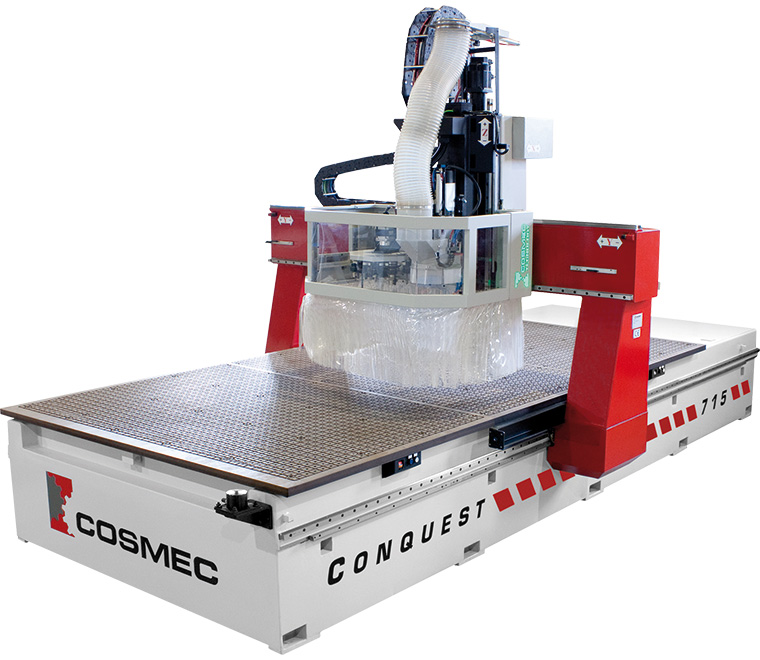

For traditional pod and rail and flat table nesting technology Cosmec has all the solutions. Since 1960 Cosmec have been producing CNC routers and can supply solutions from a standard 2440 x 1220mm flat bed entry level machine up to twin shuttle table routers and five axis technology.

The Fox range of machines has been designed to suit the small to medium size manufacturer due to its compact footprint and ease of use. Available in three bed sizes, with face drilling, horizontal drilling, automatic tool change and 10Kw router spindle all as standard. The bridge type construction makes for a solid stable machine which is capable of machining MDF, MFC, Corian, acrylics and plastics as well as other materials commonly used. The software included comes complete with the Aspan nesting option to enable easy nesting of components when required. A tool length pre-setter comes as standard for ease of tool setting.

The Conquest Range of machines has been designed to suit medium to large size manufacturers. The machine can be supplied in nesting cell format, which would include automatic loading and unloading. The machine is ideally suited to large production of kitchens and cabinet doors whilst is flexible enough to cope with most other production types. Standard features as contained within the Fox series but having a higher operating speed, pressure sensitive mats and perimeter guarding included as standard

The Smart 30 machine is a pod and rail machine which has been constructed in a modular way to allow for easy modification when bespoke or special equipment is required outside of the standard specifications.

In its most basic format the machine has the ability to face drill, horizontal drill (all four edges), groove and rout and is ideal for both flat panel and joinery products. With the addition of options such as five axis or aggregates the machine can easily manufacture stair parts or external doors and window profiles.

The easy to use Aspan software, whilst extremely powerful and intuitive in its own right, will work alongside third party software to ensure seamless programming either in the office or directly at the machine.

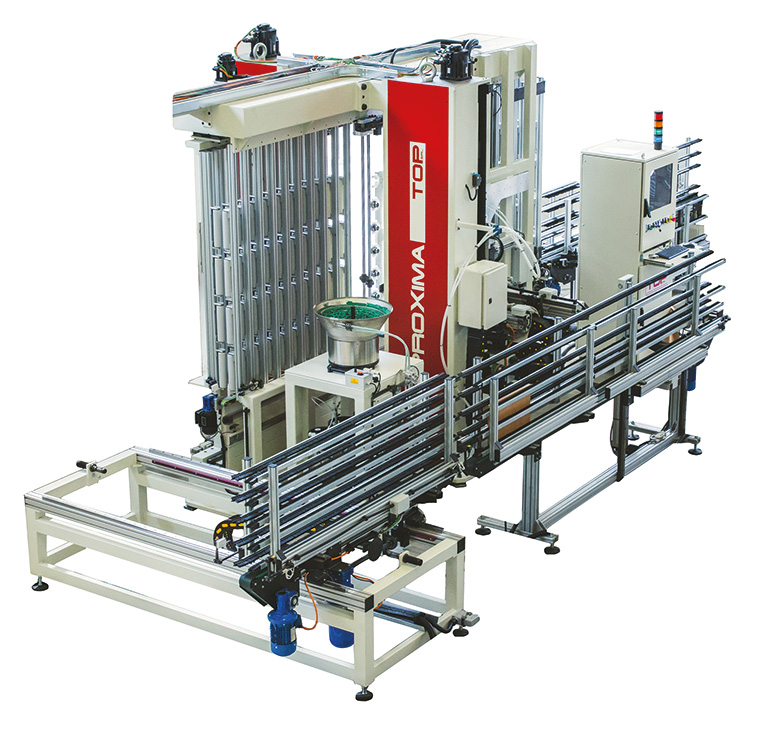

A recent acquisition to NEY is TOP Srl. This Italian manufacturer produces vertical through feed solutions for drilling, grooving, routing and insertion of hardware furniture elements.

TOP Srl was born in January 2006, with the co-operation of two associates formerly with Bre.ma and with the participation of TPA Spa – a leader in the sector of software automatisation and numerical control machines.

The original aim of TOP was to help the machine manufacturers to introduce important technological innovations into the market, to help some machine users to increase production and quality to a maximum level and to help TPA spa test and certificate electronic and information solutions for industrial use.

But now since 2008, TOP has been designing and producing CNC drilling and inserting machines for all the elements of furniture.

TOP design and manufacture special vertical CNC machines for drilling, milling, routing and insertion of dowel pins and fittings in all the elements that make up the furniture. The fundamental characteristic of TOP machines is the high degree of customisation which makes them suitable to meet the specific needs of the customer.

Thanks to its experience in the field TOP also provides service, spare parts for boring-inserting machines by different manufacturers and retrofits for second hand machines.

02476 308100

www.ney.co.uk

Cosmec’s Fox, Conquest and Smart CNC machines