The new Duomelt glue pot system from Cehisa increases workshop productivity, provides flexibility and improves the overall quality of edged boards while ultimately saving time and money.

As a leading edgebander manufacturer, Cehisa are continually refining and developing its impressive range of hotmelt machines aimed at the small-to-medium-sized panel processor. One of the most recent innovations is the development of the Duomelt glue pot.

The design of the pot is such that it allows existing residual glue to be quickly drained in just five minutes making cleaning and switching between different glue types or colours, fast and efficient. Once emptied, the new glue is up to temperature in less than 10 minutes.

The quick drain system is particularly beneficial when alternating between EVA and PUR glue. The Duomelt allows the EVA hotmelt adhesive to be quickly and easily removed from the tank before the PUR granules are added. After processing it is important to remove the PUR and purge the tank with cleaning granules to prevent the residual glue from fully reacting. Once cleaned, the remaining cleaner can be easily drained from the tank allowing EVA granules to be added. The hassle and time required for glue removal and cleaning is vastly reduced with the Duomelt.

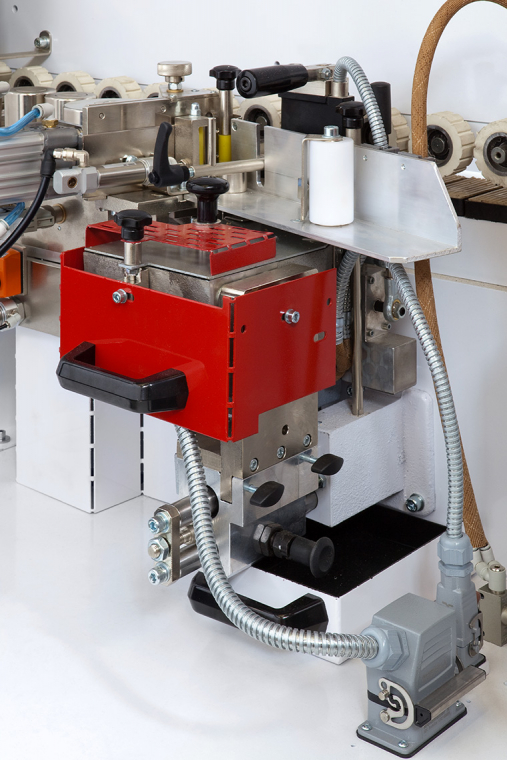

Duomelt glue system for use with both EVA and PUR glue

VA works at a higher temperature, around 190°C, compared with PUR at around 130-140°C. The Duomelt system is controlled from the on-board touch screen control with intuitive, easy-to-use temperature mapping to precisely adjust the glue temperature for optimal application. An automatic thermostatic control monitors and adjusts the glue temperature and puts the unit into stand-by when idle to prevent scorching of the glue and reducing energy consumption.

Precision machined from a single piece of aluminium, the interior surface of the Duomelt glue tank is smooth and even with no edges or shape angles to inhibit glue flow. The slope of the tank has been carefully considered to increase flow rate and ensure a consistent delivery while also minimising draining time when cleaning.

Overall energy consumption has been reduced with improved thermodynamics through the use of efficient heat transmitting materials in construction. Improved sealing of the glue tank assembly minimises moisture absorption extending the lifespan of PUR glue. In addition, all working parts in contact with the glue are Teflon coated to ensure smooth glue delivery and quick draining.

Cehisa has also incorporated a new design and layout into the Duomelt with improved performance of the glue transmission system. Glue is delivered to the panel from both the upper and lower points of the application roller that incorporates built-in heating elements to maintain optimum working temperature right at the point of adhesion.

Furniture and joinery manufacturers can benefit greatly from using PUR hotmelt adhesive. It provides unsurpassed water resistance, especially useful in kitchen and bathroom areas, is heat resistant up to 150°C, provides the highest bond strength and can leave a virtually invisible glue joint when used with Cehisa edgebanders.

The Duomelt system is available across the Cehisa range from the entry level Flexy through to the high performance Pro and Avant models.

0115 986 5201

www.daltonswadkin.com