With over 125 years of manufacturing experience, Joos has built a reputation for producing the most reliable and efficient presses in the woodworking industry. This outstanding reputation is why Homag continues to partner with Joos, as the official distributor of Joos products in the UK and Ireland.

Designed with flexibility in mind, Joos vacuum presses are ideal for producing shaped parts with a variety of wood-based or thermoplastic materials including: veneers, thin plywood, honeycombs and laminates. Furthermore, the vacuum presses are capable of the lamination of flat and shaped parts with foils, veneers and laminates.

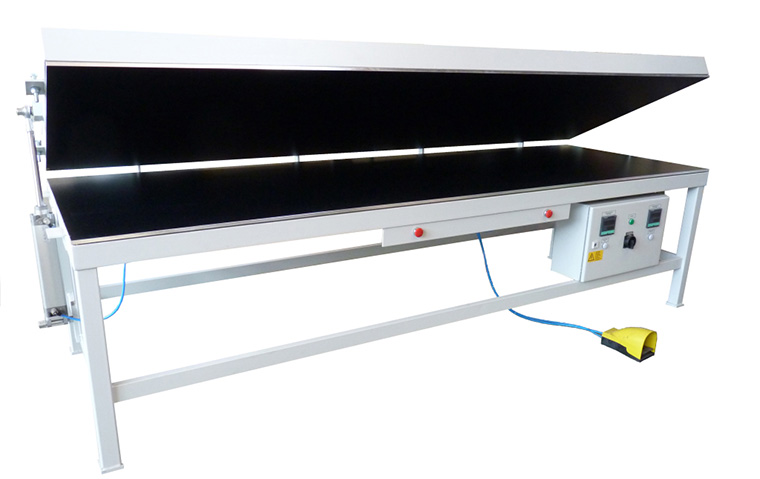

Joos heating table

The production capability of the presses also includes the creation of shaped parts from thermoplastic materials such as solid surfaces, acrylic and plastics. Additionally, these versatile machines have the ability to glue edges and profiles.

The machine range includes standard sizes for both small and large companies. However, users are also able to customise machines to meet specific production needs. The Joos VAK Heavy Line vacuum presses come with a working surface which ranges from 2300 x 1300mm to 3800 x 1300mm for a variety of manufacturing requirements.

For the industrial-sized manufacturer, Joos’ range extends to include the VAK Industrial Line. Joos also produces the Vak-S vacuum press for the specialist production of solar panels.

Innovation and creativity with Joos thermoforming technology

The Joos range of heating tables is ideal for the innovative designer who wishes to temper thermoplastics materials such as wood, solid surfaces and acrylic. Producing working temperatures of up to 180°C maximum, the heating tables provide unlimited creative opportunities.

Standard-sized heating tables come with several worksurface size options, depending on the required task. Ranging from 2500 x 1000mm to 3700 x 1000m, the customisable range of Joos heating tables can cater for any size facility.

The Joos heating tables come with a host of features to make tempering materials fast, safe and easier than ever before for the operator. A solid base frame with a small footprint makes the heating table a compact yet powerful addition to any manufacturing facility.

Additional features such as easy-opening work surface with gas pressure damper make for effortless production and material handling. With precise temperature control, monitored by the microprocessor controller, the machine table is able to perform and maintain maximum temperatures. The added bonus of energy-efficient heating power up to 3.5kW / sq m makes thermoforming technology more affordable than ever before.

Joos vacuum and thermoforming technology provides a world of manufacturing possibilities for the innovative designer.

For more information on the Joos range of vacuum presses and heating tables, contact Adele Hunt at Homag on 01332 856424 or email [email protected].