International software developer CAD+T specialises in creating highly customisable software solutions for three-, four- and five-axis CNC machines and nesting. Working closely with leading machinery manufacturers and component specialists, CAD+T’s bespoke software solutions offer customers a highly adaptable and flexible approach to automated manufacturing.

“CAD+T have always done things differently,” begins Martina Schwarz, international sales and marketing Manager at CAD+T. “We’ve never worked on the assumption that one software package could work effectively across the board. It’s simply not the case, and that’s why we’ve never offered software that centres around pre-programmed database systems.

“Instead, we’ve remained focused on delivering fully customisable software solutions that depend entirely on the business, its production rates, the machinery and tools in place and the materials being used.

“For us, it is also equally as important to understand the company’s plans for the future and short-, mid- and long-term goals. It is only by considering these factors that anyone can truly design an effective software solution in today’s market.”

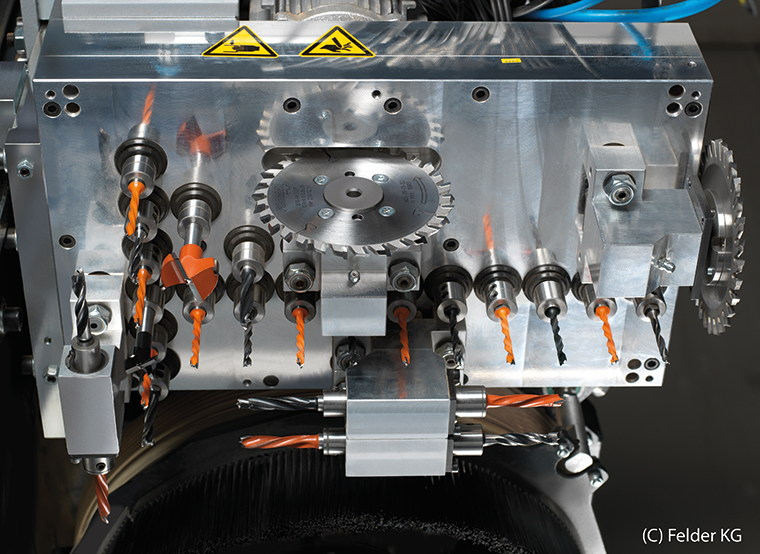

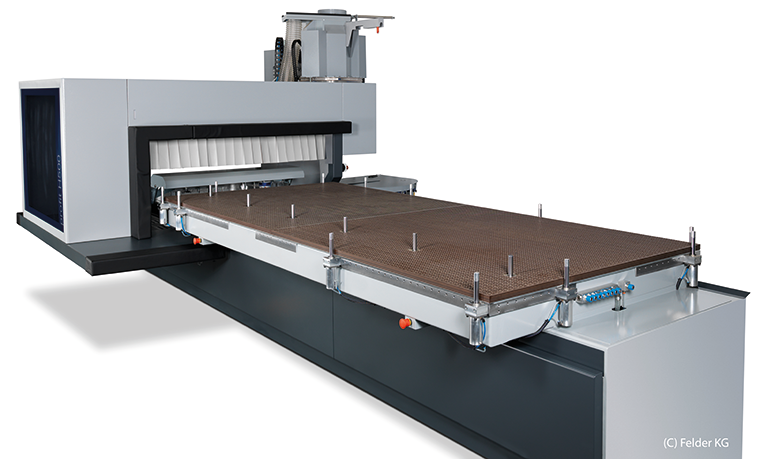

Offering the next generation in CNC software, CAD+T’s intelligent CAM interface separates components and automatically generates CNC data from the customer’s construction drawings. A database of milling strategies, machining parameters and tools generate the machine files needed to complete the job, which in turn creates a solution that does not require the programming or reorganising of CNC data.

Martina says: “This means timely manual programming and generic system inputting is a thing of the past, and the need for an experienced software programmer has been removed from the equation. This not only simplifies the manufacturing processes and streamlines production processes, but also improves efficiencies.”

The software has been designed to optimise production processes and materials output, offering time saving benefits of around 60% per order and error prevention of up to 80%. One package can also be run on several CNC machines, saving time and money throughout the production cycle.

Martina adds: “Our fully adaptable approach to software design allows us to analyse production processes and create flexible and efficient software packages that work around the most challenging requirements. When it comes to our CAM interface, it can guarantee perfect work-on results, a reduction in material waste and increased surface quality. So, whether you’re a joiner, shopfitter, interior designer, cabinetmaker or kitchen designer, we can create adaptable software solutions that reflect your business and workflow.”

For more information on CAD+T and its complete range of CAD/CAM software solutions for the furniture production and interior design markets, visit the company’s website.